FlowPlate® Lab

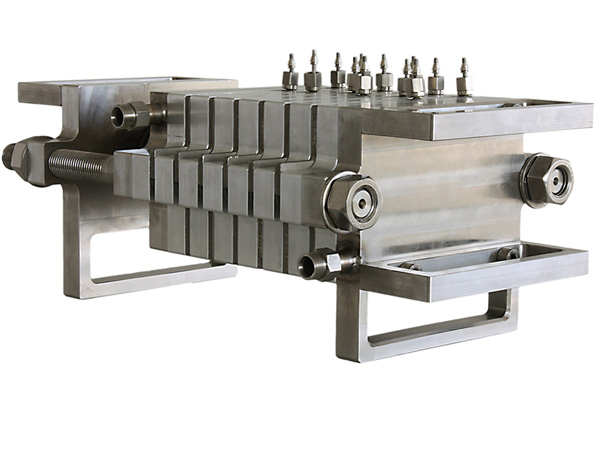

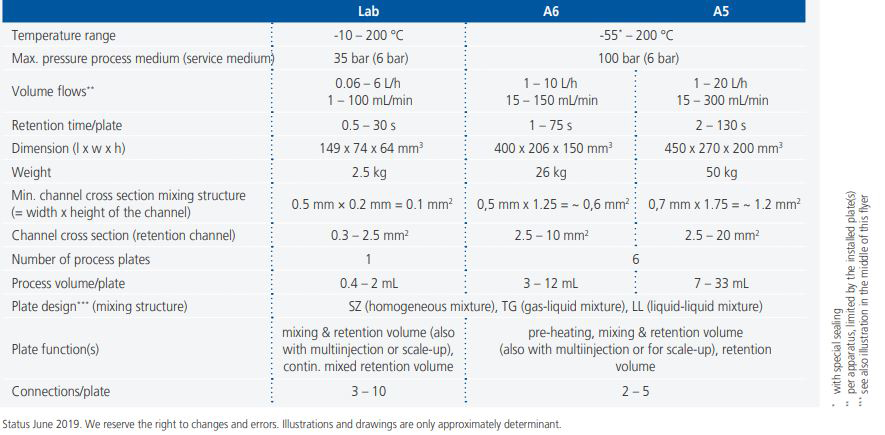

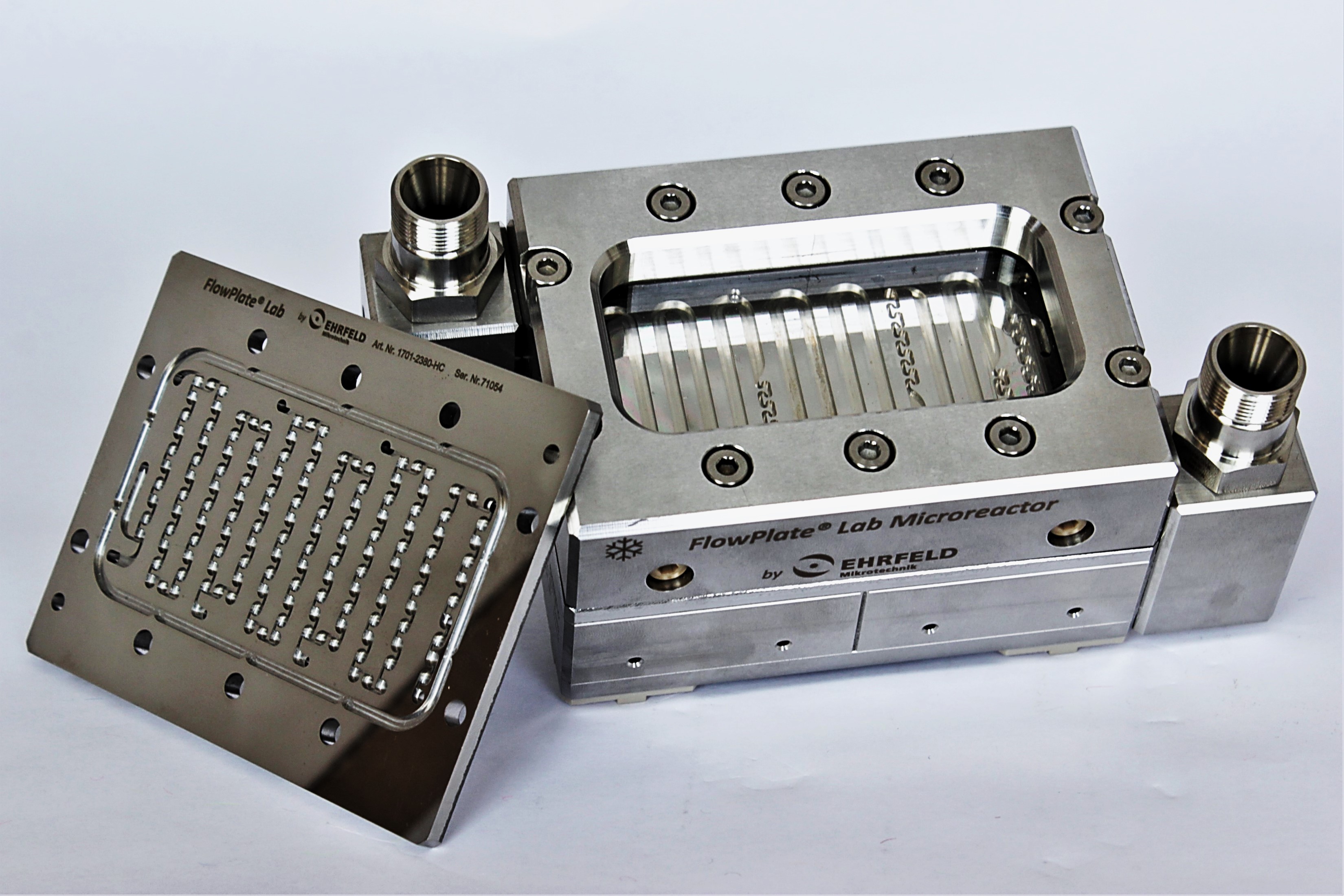

| Dimension (l x w x h): | 149 x 74 x 64 mm2 |

| Max. pressure process medium: | 35 bar (6 bar) |

| Temperature: | -20 °C to +200 °C |

| Material (process plates): | Hastelloy® |

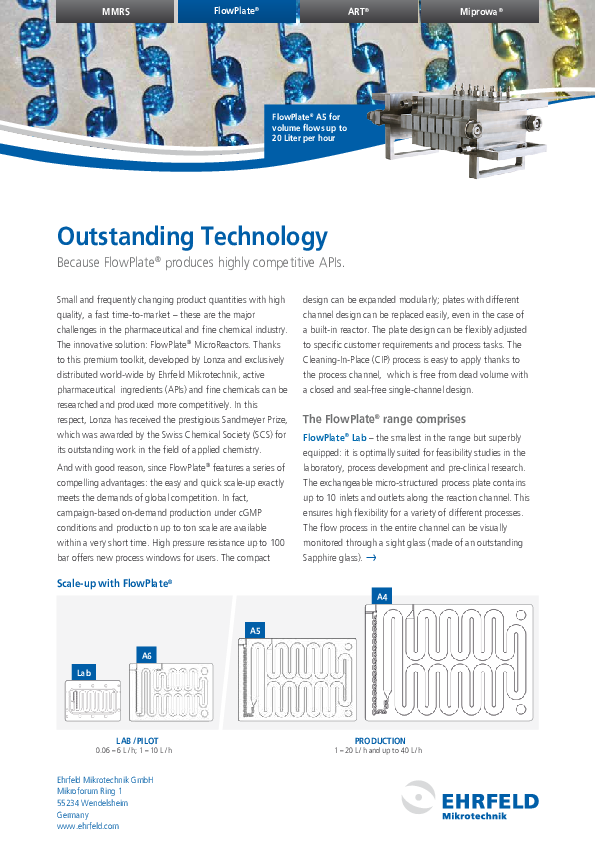

The FlowPlate® Lab is the smallest in the range and is ideally suited for feasibility studies in the laboratory, for process development and preclinical research. The exchangeable, microstructured process plate has up to ten in- and outlets along the reaction section which ensures high flexibility for a wide range of processes. A viewing window made of durable sapphire glass allows the operator to visually monitor the flow process in the entire channel.