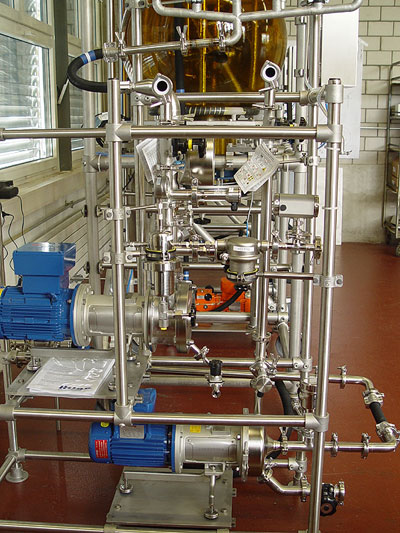

UV sensitive chemicals processing

Round flasks reactors with stained glass

| Size: | 200 liter |

| Pressure: | -1 to +0.5 bar |

| Temperature: | -10 to +200 °C |

| Material: | Borosilicate glass 3.3, stainless steel |

Round flask glass reactors with stained glass are used for processing of UV-sensitive chemicals. These round flasks with immersion heaters are used as reactors in ATEX zone 1. Heating cartridges inside the large glass flasks ensure fast and precise process temperature control. The flasks are installed on load cells for continuous weight control and dosage.