Typical applications

- Thermal hazard screening

- Risk analysis

- Process safety

- Runaway scenario screening

- Scale-up studies

- Thermal stability evaluation

- Warehouse tests

SYSTAG provides precise calorimeters with accurate information about the thermal behaviour of substances to evaluate the possible implementation of your process in a reactor system.

Experimental conditions

Depending on the specific characteristics of the material or process, experiments can be performed under various controlled conditions:

The operator is provided with a large variety of useful information on the process or the substance under investigation for subsequent characterisation.

When to use FlexyTSC:

The adiabatic thermal screening calorimeter is a powerful tool for assessing the safety characteristics of solids, liquids, and heterogeneous mixtures.

With FlexyTSC, detailed thermodynamic investigations can be carried out to identify and evaluate potential risks arising from decomposition processes or self-accelerating (autocatalytic) reactions.

The FlexyTSC becomes essential whenever deeper understanding of thermal behaviour or potential reaction hazards is required. Typical evaluation parameters include:

| Features | RADEX V5 | RADEX V6 | SEDEX |

| Temparture range | RT ... +400°C | -50 ... +190°C | RT ... 400°C (with cooling -10°C...+150°C) |

| Measurement | Pt-100 probes | Pt-100 probes | Pt-100 probes |

| Sensitivity | 0.05°C or 2 mW/g | 0.05°C or 2 mW/g | 0.05°C or 0.5 mW/g |

| Net volume | 2.5 ccm (1.5 to 3 ccm) | 2.5 ccm (1.5 to 3 ccm) | 20 ml (from 2 to 100 ml or more) |

| Design | V4A steel jacket with heated metal block | V4A steel jacket with heated metal block | Air circulation oven with pressure relief |

| Cooling | Cooling fan | External thermostat | Cooling unit (to approx. -10°C) |

| Sirrer | - | - | Magnetically operated |

| Weight | approx. 3.5kg | approx. 13kg | approx. 54kg |

| Dimensions (HxWxD) | 250 x 150 x 150 mm | 340 x 200 x 340 mm | 530 x 420 x 500 mm |

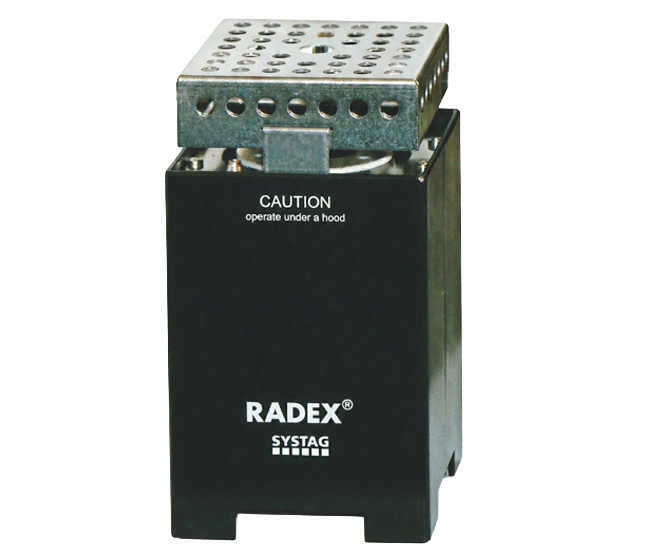

Temperature range: 25 to 400 °C

Volume range: 1.5 – 3 mL

The RADEX V5 measuring cell enables cost effective and safe thermal evaluations from ambient temperature up to +400 °C. Typically low sample volume requirements of 2.5mL make it ideal for routine testing and screening.

One of its major advantages is the low cost of the vessels, allowing to be discarded when cleaning is not feasible. A built-in cooling fan ensures rapid cooldown after each experiment, increasing overall throughput.

Temperature range: -50 to 190 °C

Volume range: 1.5 – 3 mL

Cooling: External thermostat

The RADEX V6 is designed for safe evaluations at low to medium temperatures, ranging from –50 °C to +190 °C. The insulated design prevents freezing of the vessel and ensures accurate, reliable measurements even under deep cold conditions.

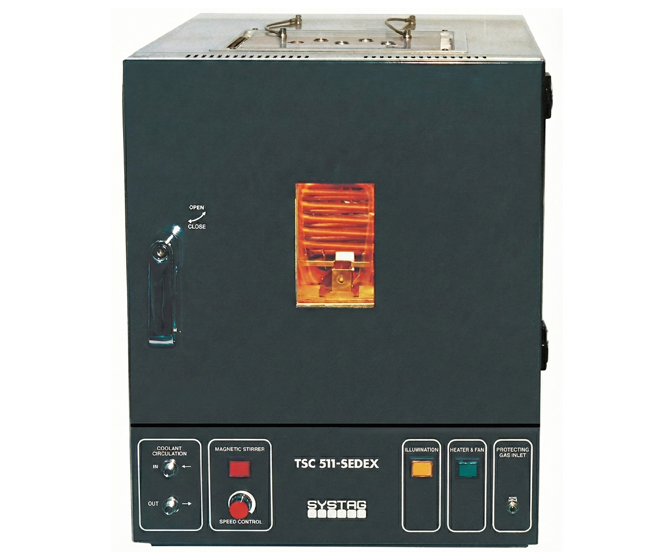

Temperature range I: 35 to 400 °C

Temperature range II: -10 to 190 °C

Volume range: 2 – 100 mL

SEDEX is the most versatile measuring cell in the portfolio. It features an integrated display for real time progress monitoring and a magnetic stirrer for improved sample homogeneity. By using an oven with circulating hot air, solid samples can be tested for stability (e.g., transport stability in a wire cage). Two different temperature ranges make SEDEX suitable for a wide range of applications.