Products

Pressure reactors / stirred autoclaves

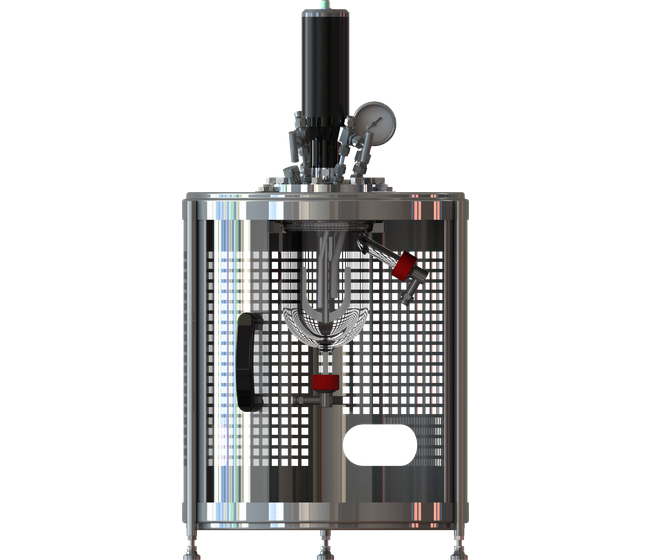

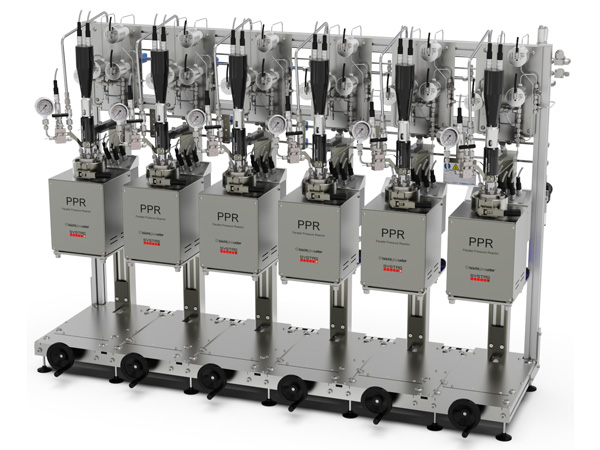

Buchi pressure reactors / stirred autoclaves are used for reactions and various applications under pressure. Our pressure reactor systems are designed for intensive daily use in laboratories, pilot plants / kilo labs and small-scale production facilities. Customized solutions for your specific process requirements.

Lab and pilot pressure reactors 0.25 - 500 liter

High pressure reactors 100 ml – 5 liter

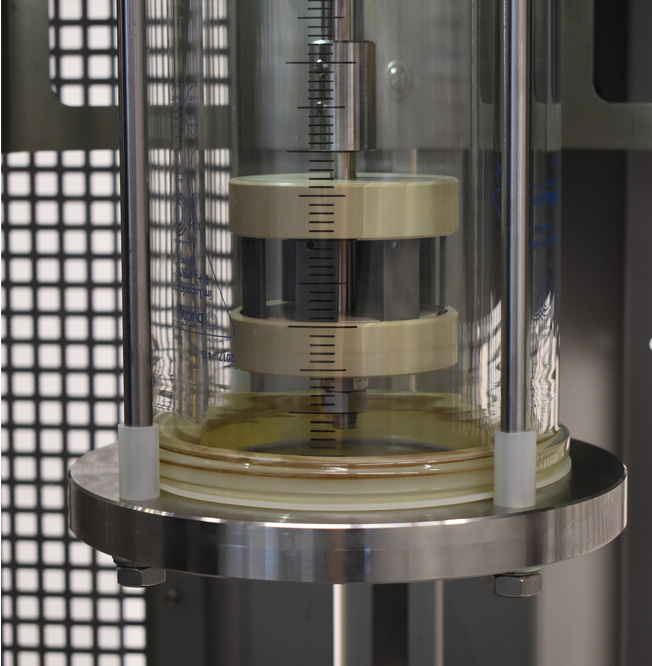

Metal-free (inert) pressure reactors 100 ml – 20 liter

Magnetic couplings & magnetic stirrer drives

Corrosion testing autoclaves

Accessories for pressure reactors

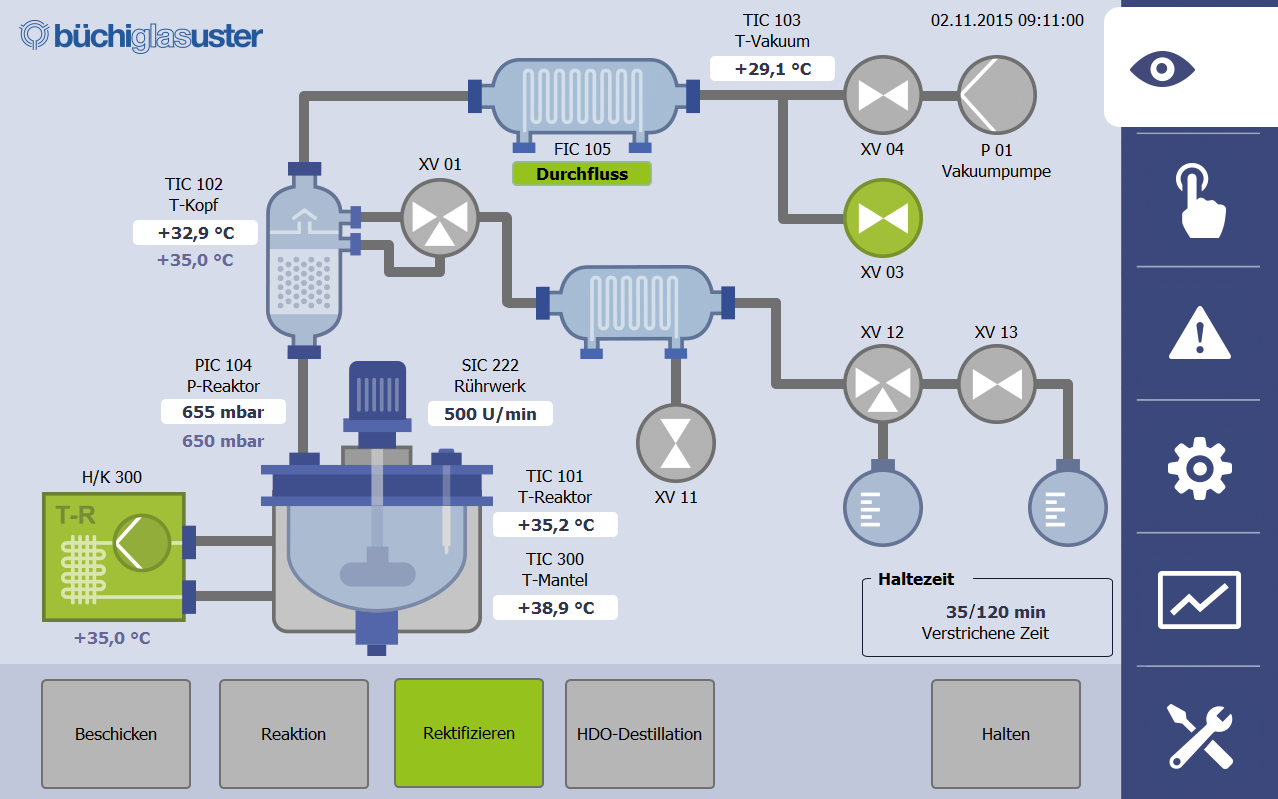

Measure, control & automation

Product filter pressure reactors / stirred autoclaves

Videos

Büchi AG - buchiglasuster® - Reactor Systems and Pilot Plants for the chemical and pharma industry

Büchi Pressure Reactors (English)