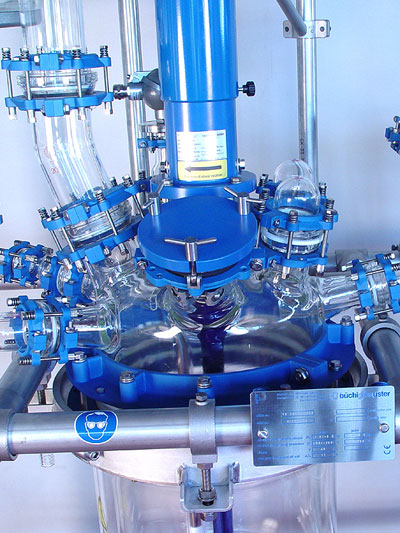

chemReactor BR - basic glass reactor system

Basic glass reactor systems for API synthesis, small scale production and pilot plantasic glass reactor system

| Glass reactor: | 15, 30, 60 liter |

| Pressure: | -1.0 (FV) to +0.5 bar |

| Temperature: | -60 °C (-90 °C) to +200 °C |

| Material: | Borosilicate glass 3.3, glass-lined steel, PTFE, PFA, Tantalum |