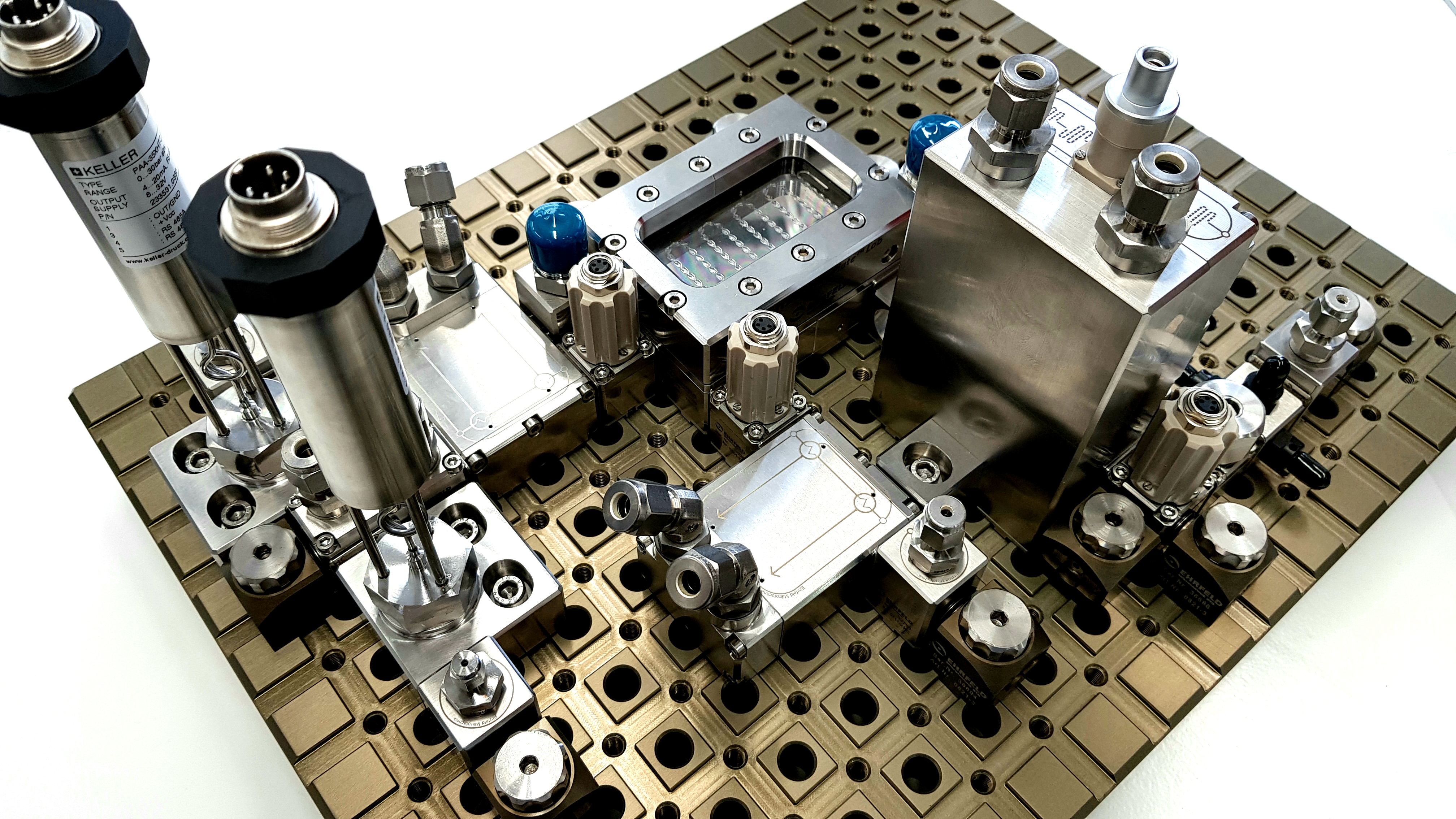

Modular MicroReaction System – MMRS

Innovative building kit for lab use, pilot plants and production

| Base plate dimension (l x w)*: | 212 x 162 / 325 x 212 / 425 x 325 mm2 |

| Max. pressure process medium: | up to 100 bar |

| Temperature: | -20 °C to +200 °C (**optional -60 °C to 600 °C) |

| Material (in contact with process medium): | Stainless Steel A4 or Hastelloy® C276/22, FFKM, PTFE |

* Other dimensions on request; depending on the module composition, the height varies

**Only modules with special sealing material and/or specific modules

Typical applications

- Mixing, emulsification, dispersion, particle precipitation

- Homogeneous / Heterogeneous synthesis (also with catalyst and/or multi-step)

- Photochemistry