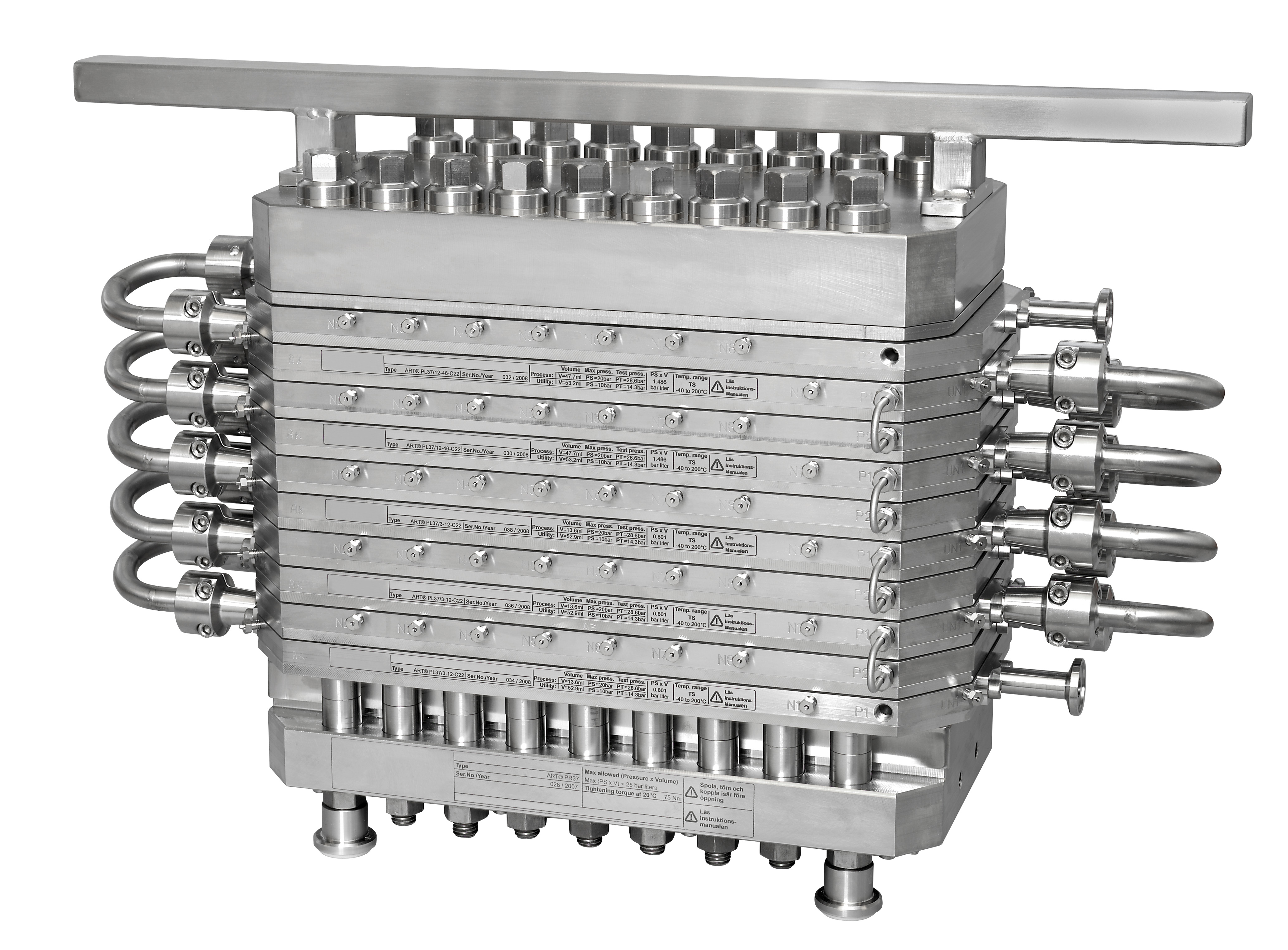

ART® Plate Reactors PR37

| Dimension (l x w x h): | 550 x 170 x 240/370 mm |

| Max. pressure process medium (service medium): | 20 bar (10 bar) |

| Temperature: | -60 °C to +200 °C |

| Material (process plates): | Hastelloy® |

The modular and versatile ART® Plate Reactors are milli-structured plate reactors with excellent heat transfer, optimal residence time distribution and faster mixing than conventional techniques, designed for quick and easy scale-up. The reactors are made of Hastelloy which leads to a robust design. ART® Reactors enable a broad spectrum of reaction categories, from research and development to production applications allowing for different temperature zones within the same apparatus.

The result is a significantly intensified process in terms of yield, costs and safety. Multiple injection, multi-step reactions and sampling in mid-process are possible due to additional ports. Efficient process control enhances options for monitoring and can be easily integrated. The implementation in multi-purpose plants allows flexible product changeovers. Additionally, the reactors can be completely disassembled, simplifying the cleaning process.

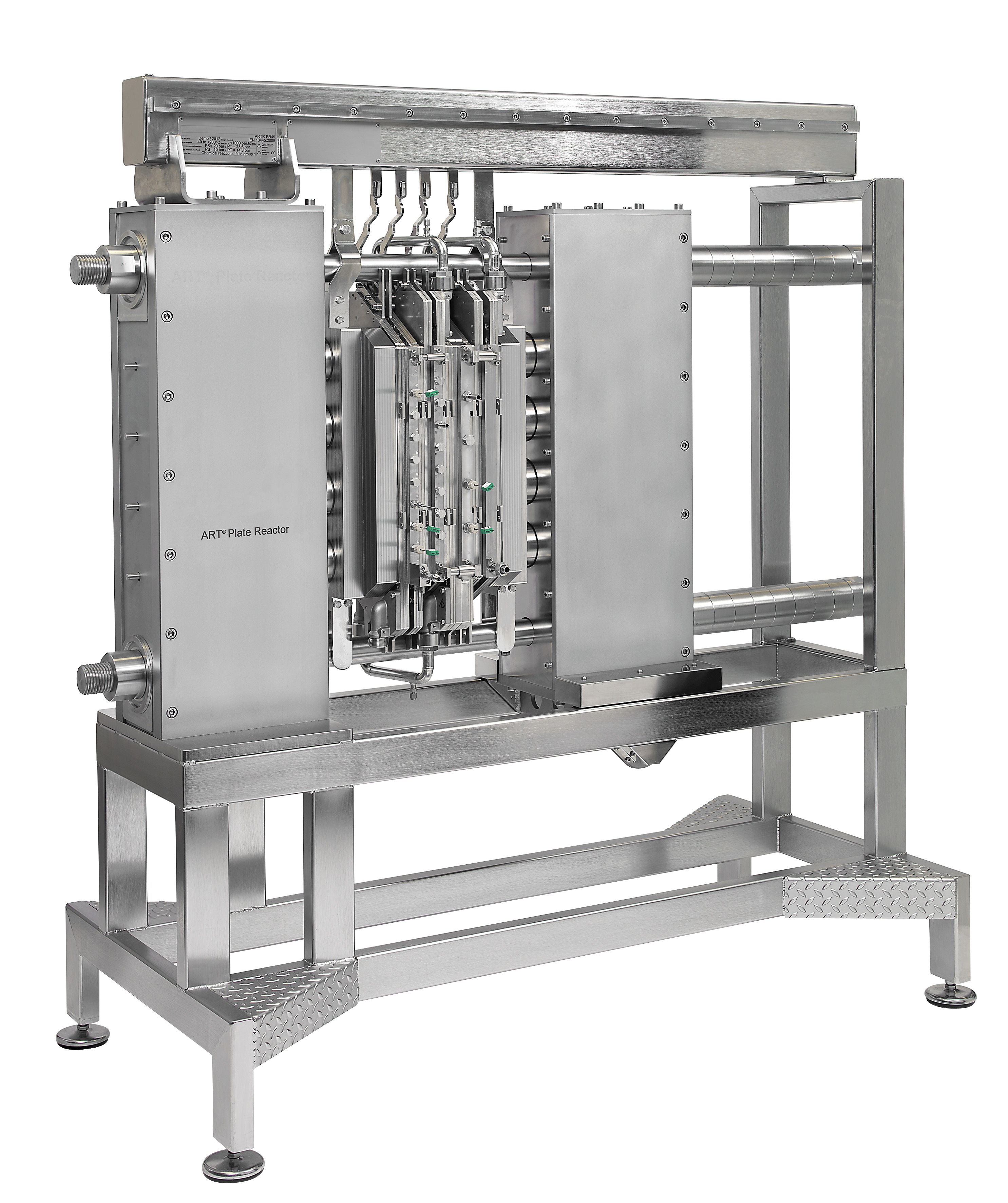

The Art® series includes the Art® Plate Reactor PR37 for laboratory and pilot scale applications and the Art® Plate Reactor PR49 for production scale.

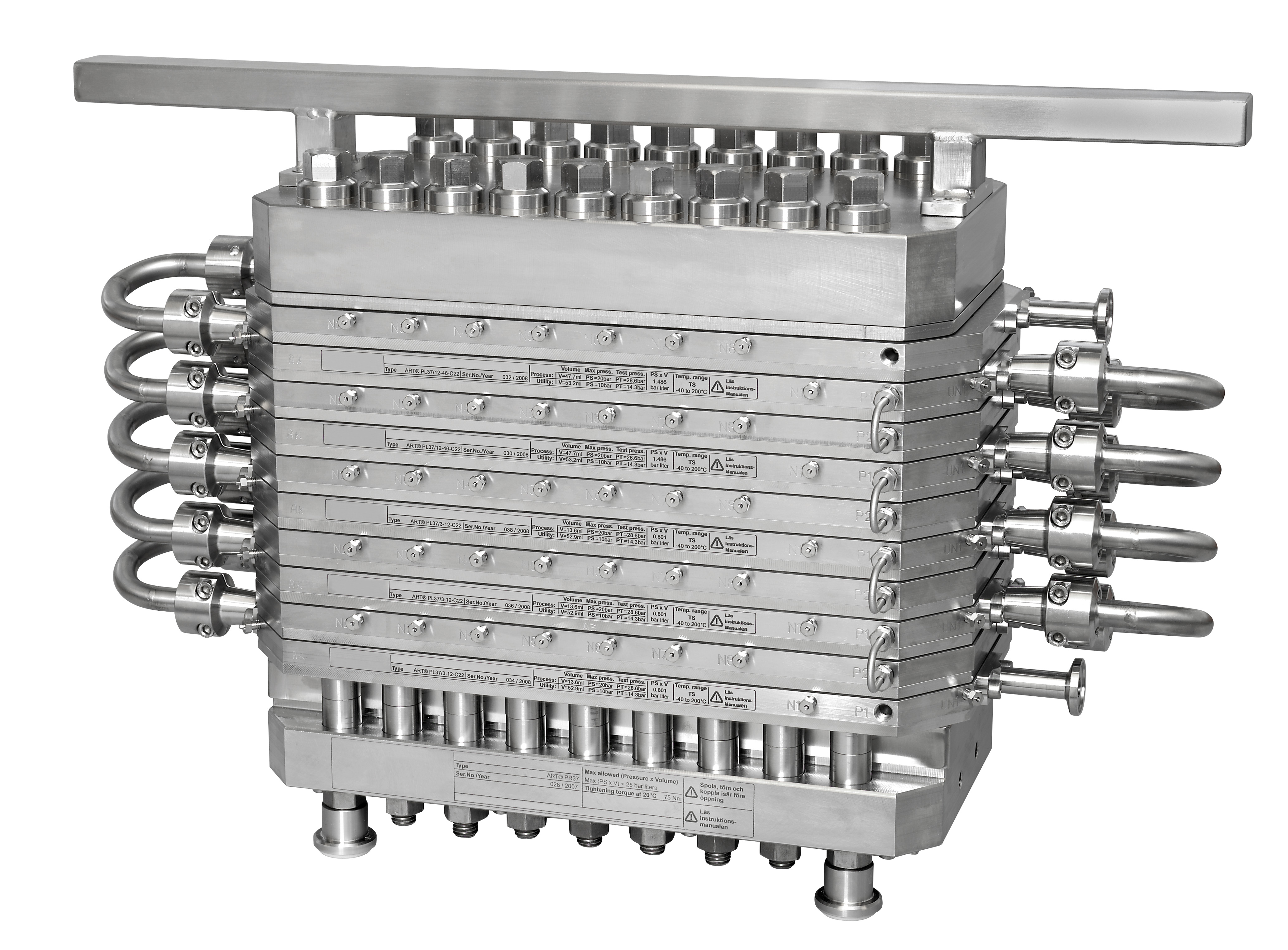

| Dimension (l x w x h): | 550 x 170 x 240/370 mm |

| Max. pressure process medium (service medium): | 20 bar (10 bar) |

| Temperature: | -60 °C to +200 °C |

| Material (process plates): | Hastelloy® |

| Dimension (l x w x h): | 1930 x 800 x 1830 mm |

| Max. pressure process medium (service medium): | 20 bar (10 bar) |

| Temperature: | -40 °C to +200 °C |

| Material (process plates): | Hastelloy® |

For more information about the ART® - flow plate reactor, please visit the Ehrfeld website.