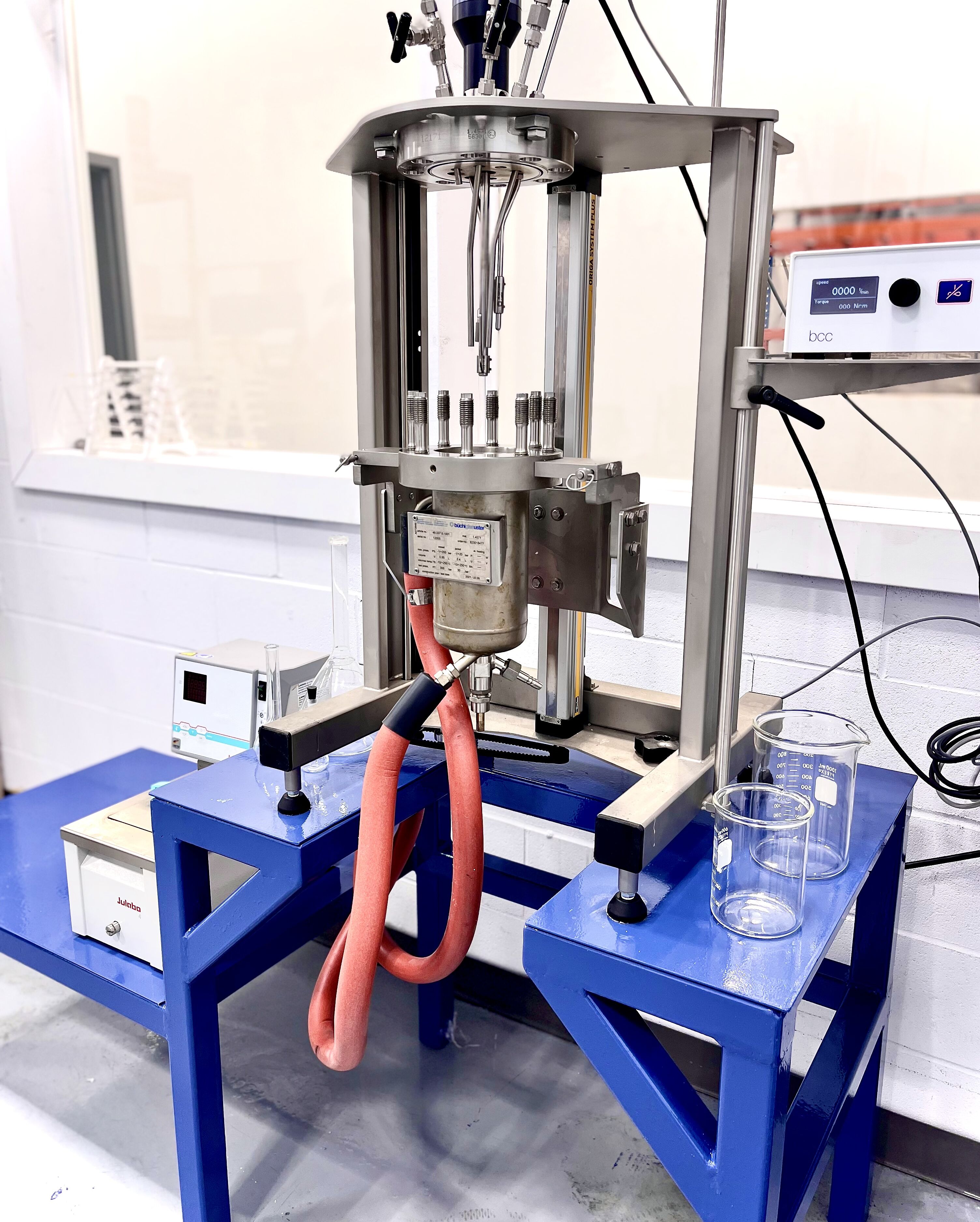

“We are very satisfied with our Buchi versoclave system which allows us to perform various types of reactions (controlled and free radical polymerizations, hydrogenation…) thanks to the pressure and temperature ratings as well as the high torque stirrer. We have two reactor sizes (1L and 3L vessels) that are easily switchable and that we frequently use to study the influence of the reaction medium volume. The safety features, the ease of use, and the reactor lift are additional assets that make this apparatus indispensable within our R&D department.”

Adrien Metafiot, Chemist, R&D Laboratory, ADFAST Corp.