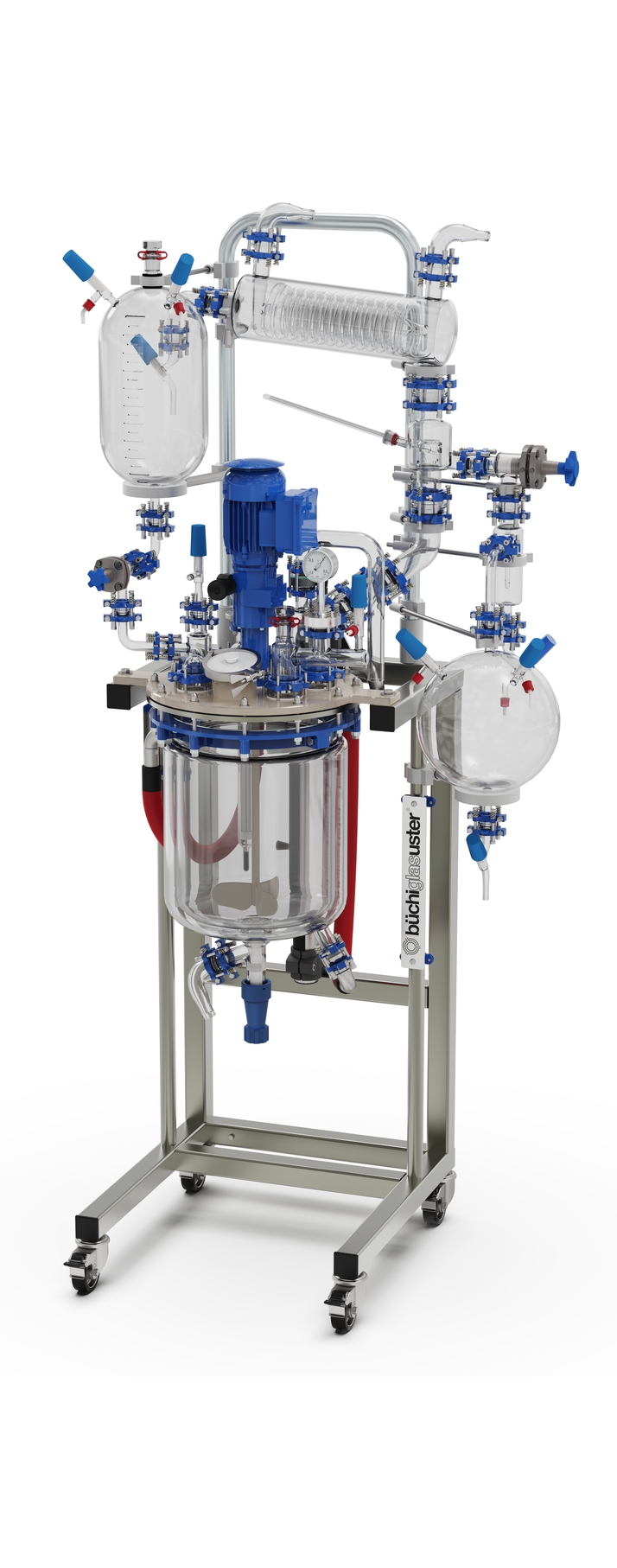

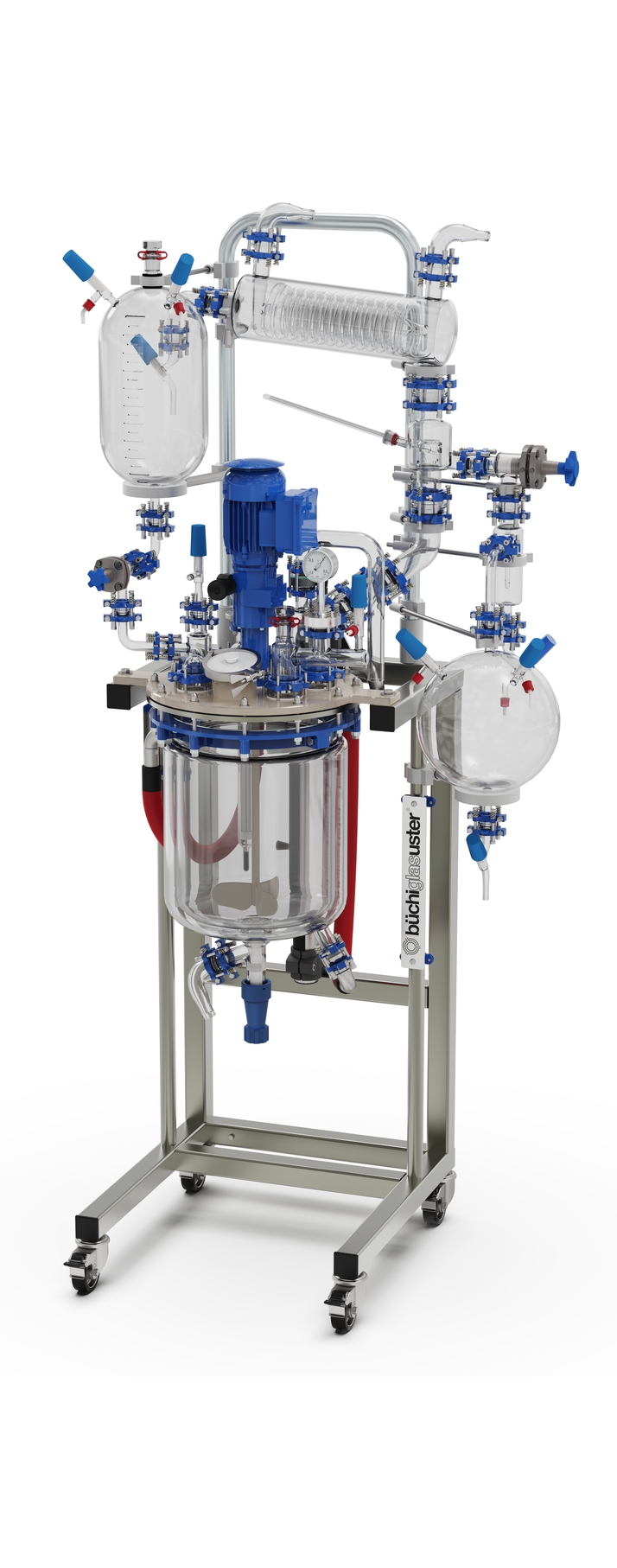

midiPilot® - glass reactor for small volumes

Multipurpose glass reactor for small volumes

| Glass reactor: | 20 to 30 liter |

| Pressure: | -1.0 (FV) to +0.5 bar |

| Temperature: | -60 °C (optional -90 °C) to +200 °C |

| Material: | Borosilicate glass 3.3, PTFE, PFA |

| Glass reactor: | 20 to 30 liter |

| Pressure: | -1.0 (FV) to +0.5 bar |

| Temperature: | -60 °C (optional -90 °C) to +200 °C |

| Material: | Borosilicate glass 3.3, PTFE, PFA |

A clean-room setup and other materials are available to meet your specific process requirements.

The midiPilot® is our sturdy multipurpose glass reactor for small volumes. It is specifically designed for applications in kilo lab, for chemical process development and cGMP compliant API syntheses.

The reactors' explosion proof design (ATEX) and inert materials allow safe processing of solvents and acids in a completely sealed reaction vessel.

The compact reactor system can easily be modified: interchangeable reaction vessels of 20 and 30 liter including interchangeable stirrers are available. The glass reactor is equipped with a lifting / lowering device for easy and efficient opening and cleaning.

We produce complete solutions for chemical processing: Reactor systems including accessories like sampling devices, pH probes, rectification columns with structured packing, process monitoring and control as well as integration of auxiliary equipment such as temperature control units, nutsche filters / dryers, gas scrubbers or mixing vessels.

Optional distillation overhead consisting of:

Optional distillation overhead consisting of:

"For us, key factors were dosing accuracy, temperature control, vessel material, and ease of use and maintenance. We’re using the equipment to produce a sensor component in the diabetes industry.

We chose Buchi after a careful selection process with peers. Their reputation for high-quality reactors and reliable solutions played a big role in our decision.

What really stood out was the support from Buchi. They were extremely helpful throughout troubleshooting, setup, and training, always communicating clearly and offering expert guidance.

Overall, I’m very satisfied with Buchi — from selection to installation and programming, everything went smoothly, and the team was there every step of the way."

Bonita Ortega, Lab Technician, Medtronic

Buchi midiPilot - glass reactor for small volumes

buchiflex

Do you have any questions? Would you like to get in touch with us personally? Ask our specialists. We look forward to hearing from you!