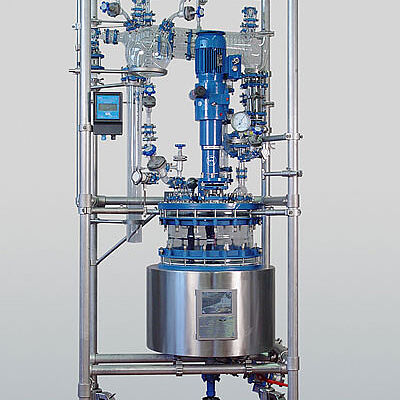

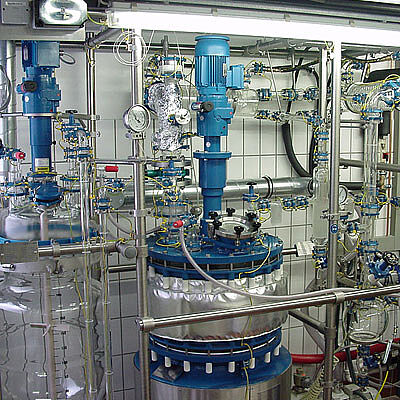

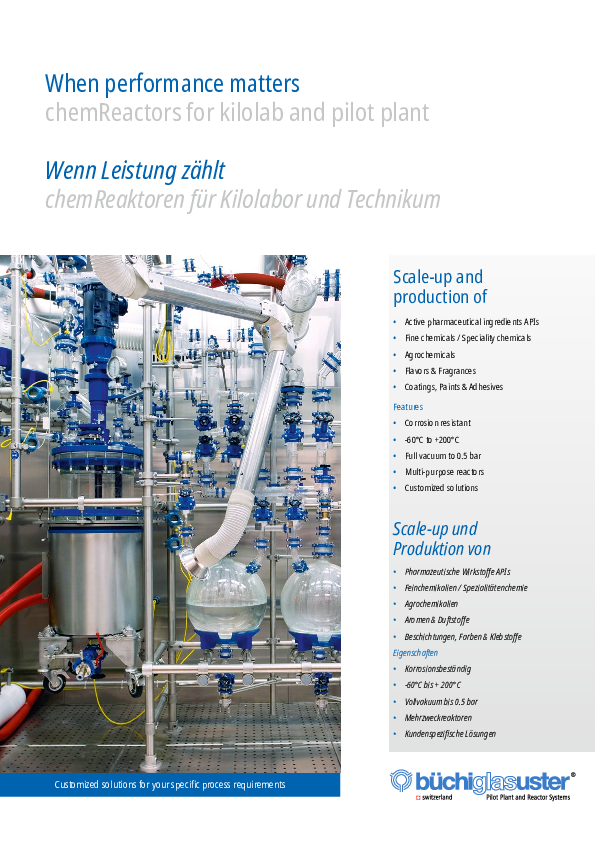

chemReactor CR - high-performance reactor system

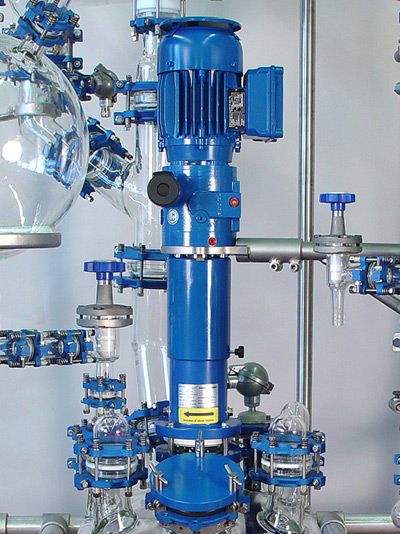

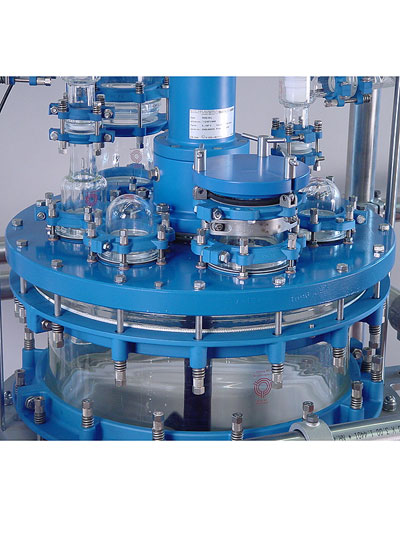

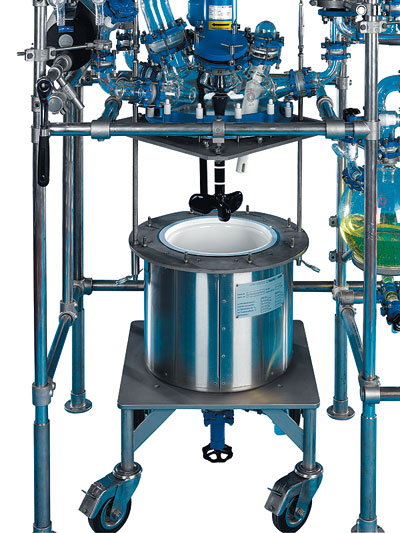

High-performance reactor systems for API synthesis, small scale production and pilot plant applications

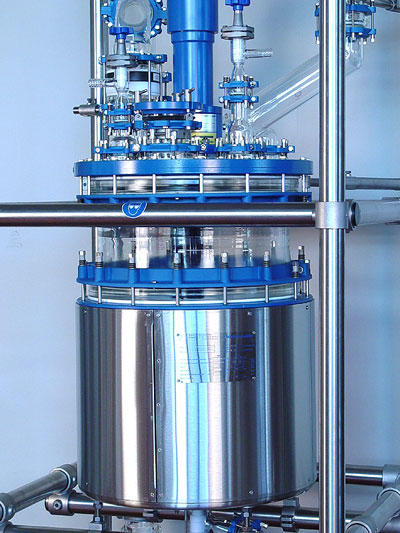

| Glass, glass-lined steel reactor: | 15, 30, 60, 100, 160, 250 liter |

| Pressure: | -1.0 (FV) to +0.5 bar |

| Temperature: | -60 °C (-90 °C) to +200 °C |

| Material: | Borosilicate glass 3.3, glass-lined steel, PTFE, PFA, tantalum |