Automated lab reactors

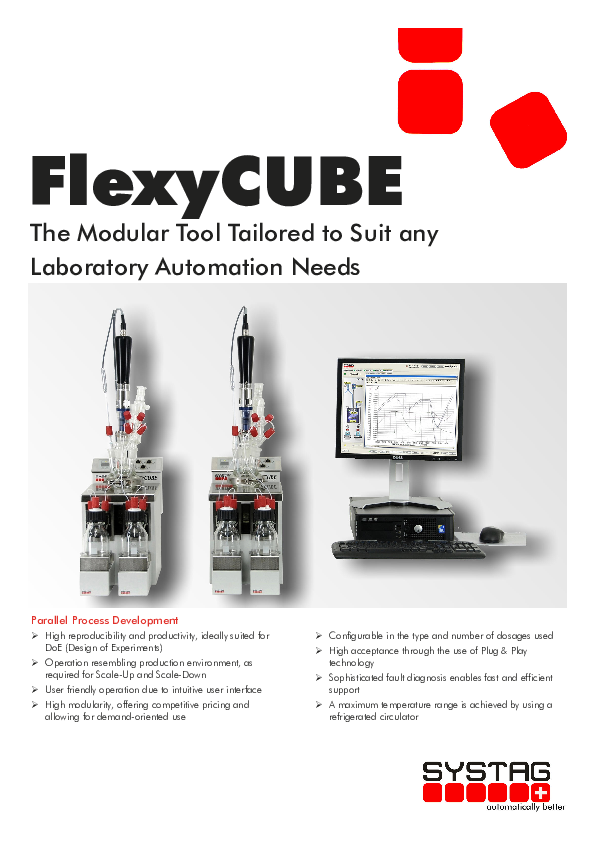

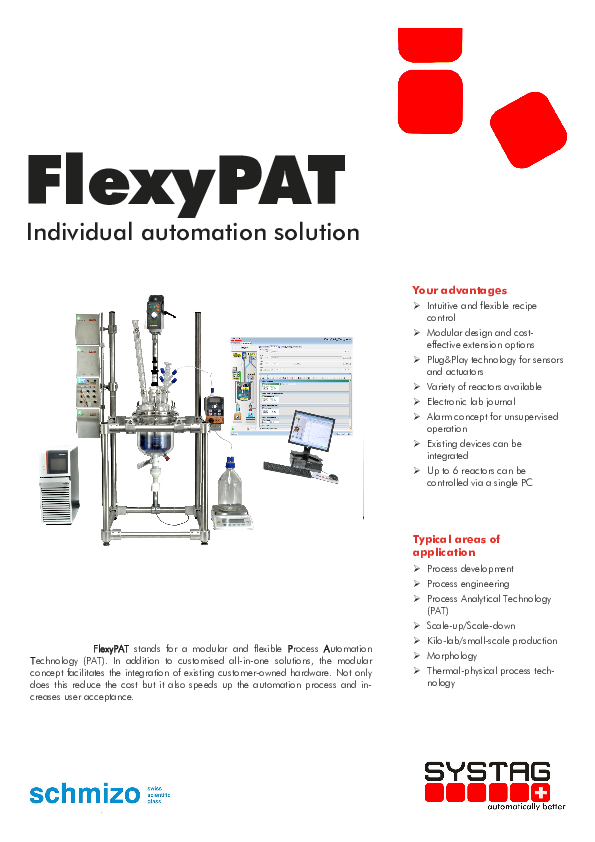

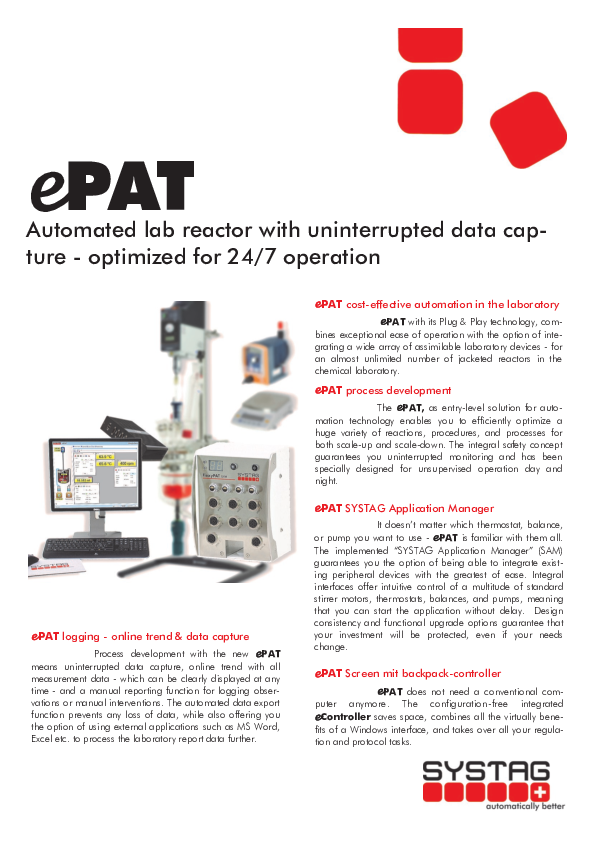

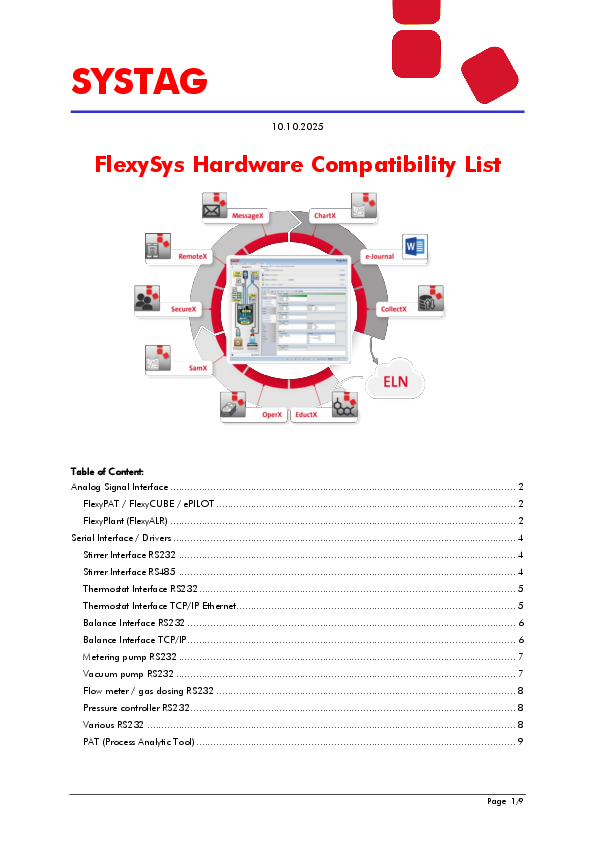

SYSTAG is our competent partner for sophisticated automation solutions. SYSTAG’s specialization and expertise in advanced process automation solutions has made it a preferred partner for the chemical and pharmaceutical industries. The company offers systems that enhance efficiency and safety at every key stage from development through piloting to production, including all chemical process development aspects associated with reaction scale-up.