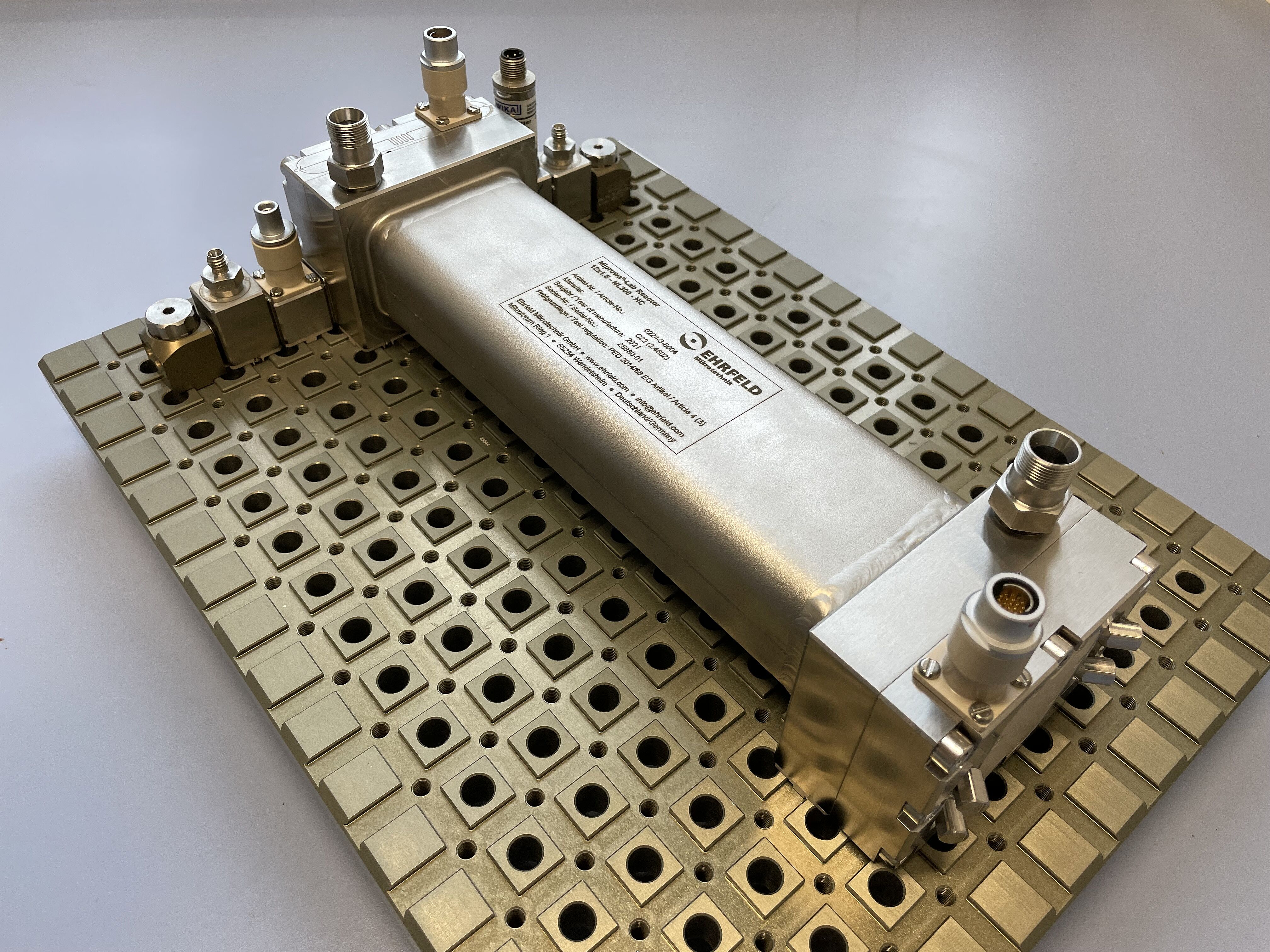

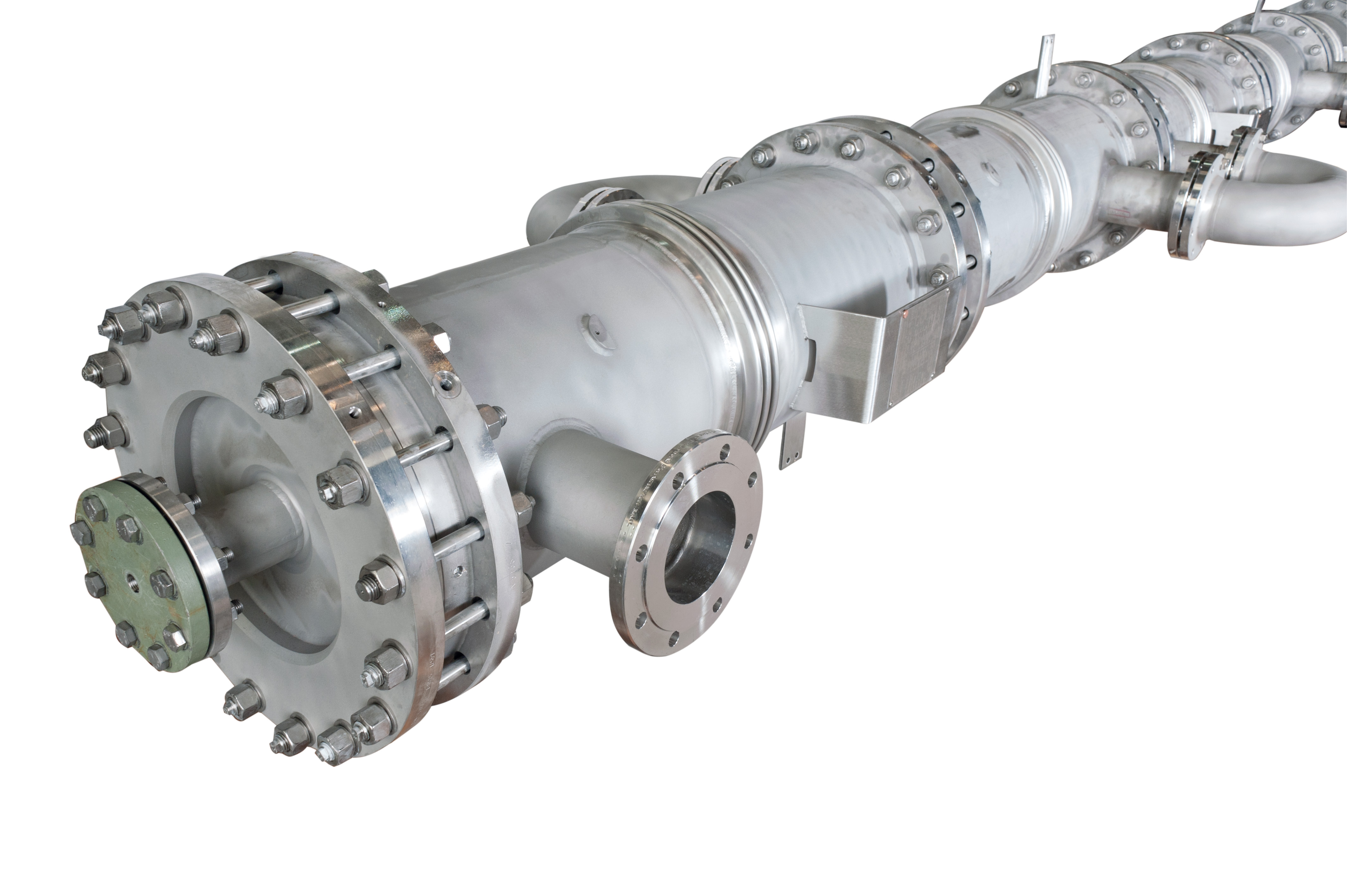

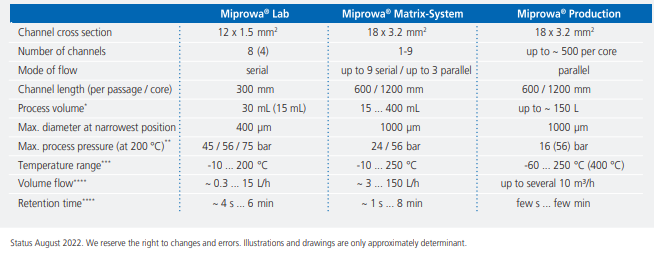

Miprowa® technology, known for its rectangular cross-section, is optimally suited for fast, highly exothermic and endothermic reactions that require excellent heat transfer. Customization of the high-performance devices is possible thanks to their flexible modularity. The inserts inside can be varied specifically to suit the requirements of the product involved.

The Miprowa® technology is manufactured from materials such as stainless steel and Hastelloy, leading to compact and robust devices. The integrated scale-up concept guarantees a quick and easy scale-up within similar channel geometries from the smallest scale to production level. By placing the necessary number of channels in parallel channel bundles inside one reactor, the throughput is increased to the desired quantity. These compact devices master an annual production of up to 20.000 t/a effortlessly.

Are you looking for more than standard products?

We develop customized solutions precisely aligned with your processes and requirements.

get in touch with us