ATEX compliance - ATEX proofed reactors

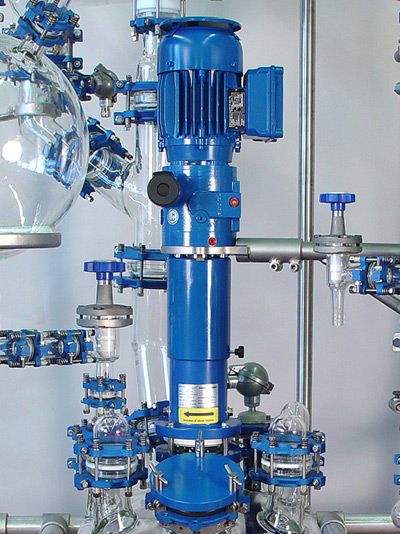

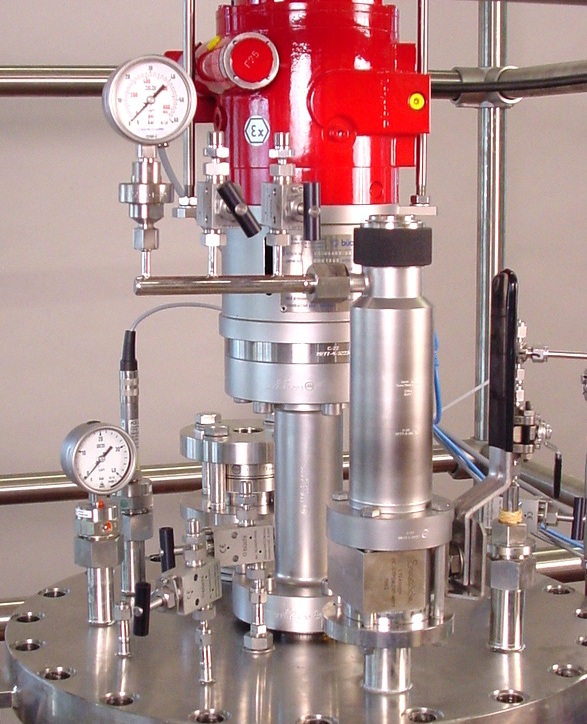

Agitator shaft seal, stirrer drives, agitators

A stirrer drive consists of:

- Ex motor with ex proof speed reducer for manual speed adjustment or with a frequency converter for electrical speed adjustment and measuring of the stirrer speed and torque

- Ex proof agitator shaft seal keeping the reactor tight against the atmosphere and dry running to avoid any contamination of the chemical process and product

- stirrers for best heat transfer into the product and efficient mixing of the chemical components